Type of Heaters

Refinery and Petrochemical Heaters

Reaction Heaters

Steam Reforming Heaters

Steam Reforming Heaters for Ammonia, Methanol, CO, Hydrogen Plants. Under Process design of:

Ethylene Cracking Heaters

Under Process design of:

Waste Heat Recovery Units

What is Revamping?

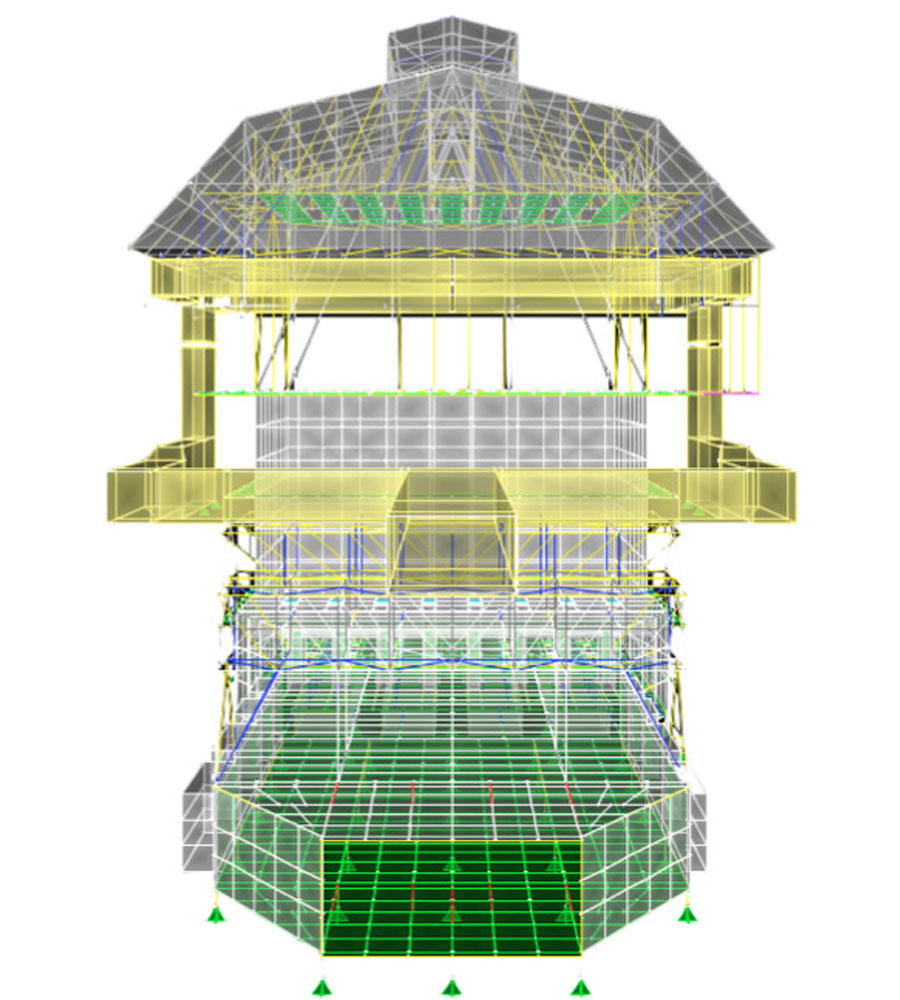

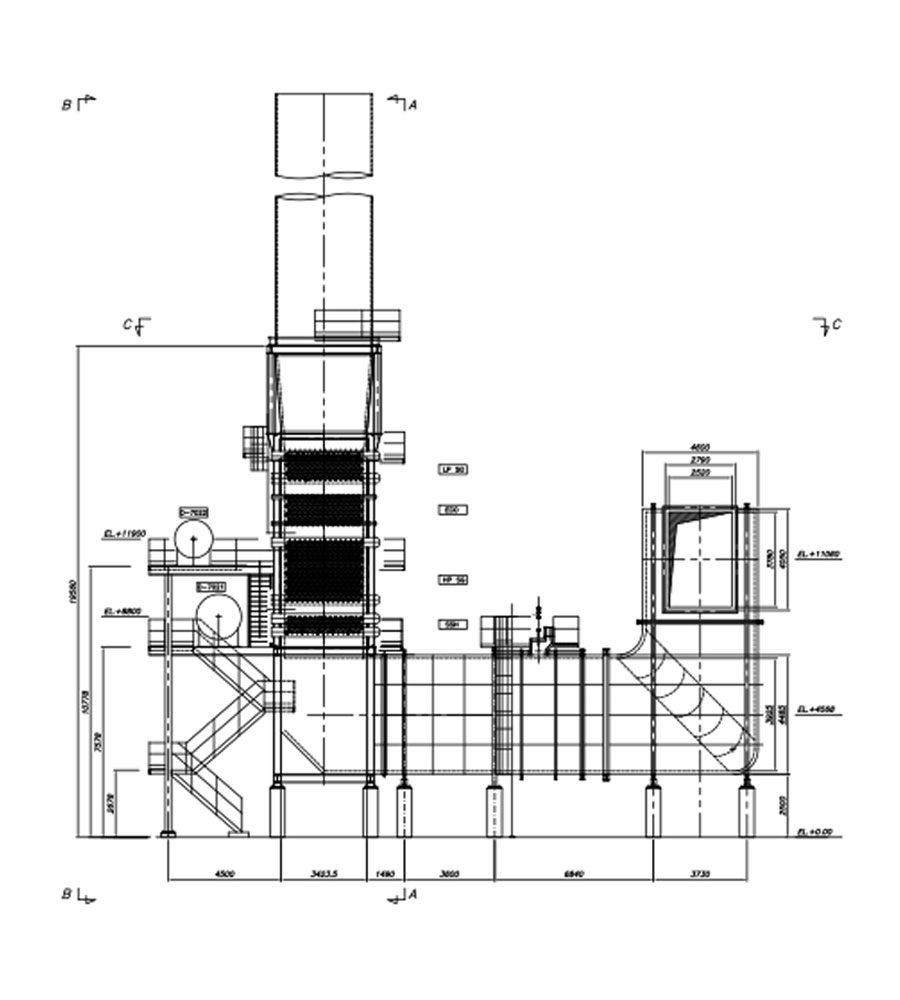

Revamping is the update of an existing Fired Heater to improve efficiency and/or capacity, through the

modification or replacement of some of its parts.

Revamping is applicable to existing fired heaters, done by us or by others, as:

- Refinery Fired Heaters;

- Steam Reforming Heaters for Hydrogen, Methanol or Ammonia Plant;

- Ethylene Cracking Heaters;

- Others;

The result of the revamping:

- Efficiency increased up to 90% and more. This means less fuel consumption;

- Quick Payback. Raising efficiency from 75% to 90% normally has a payback < 2 years;

- Reduction of pollution. Thanks to a better combustion obtained with Forced Draft Low Nox burners that

use lower excess air;

- Reduction of Stack Temperature: Higher efficiency means colder flue gas exiting the stack;

- Increasing of heater life;

Spare Parts

Our organization is not limited to the execution of turn-key projects: we have a wide range of other after-sales services that we can grant to our Clients too.

Users can contact our engineers that, utilizing our proprietary know-how, can perform studies leading to process modifications, increasing of capacity of existing heaters, debottlenecking, energy recovery, improvements of environmental impact etc.

We maintain a complete file of the projects executed along the years: we have a specific department dedicated to spare parts only, which can supply spare parts of our heaters identifying any needed piece through our in-house documentation, adopting accelerate procedures if a short-term delivery is required.

We can easily guarantee that we can supply spare parts for the entire life of the goods. We can also supply spare parts for equipment designed by others.

We take care of the after sales support directly from our head office in Milan, with the logistic and business assistance of our local agent.