Profile

(1954-2014)

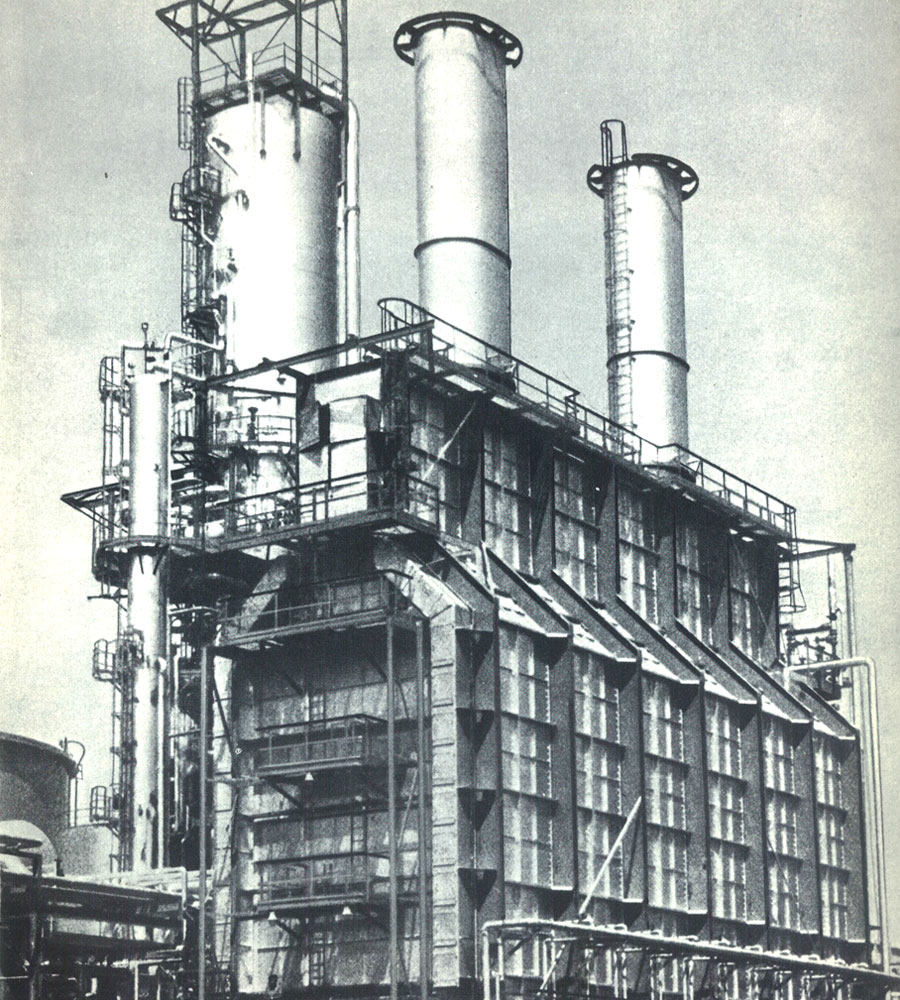

Established in Milan, Italy in 1954, KIRCHNER ITALIA is a leading engineering company

specialized in the supply of Fired Heaters, Steam Reformers and Heat Transfer Equipment for

Refineries and

Petrochemical Plants.

The Company can carry out design, engineering, fabrication, installation and start-up of Fired

Heaters for a

wide range of applications in the Oil, Gas and Petrochemical Industries.

KIRCHNER ITALIA deploys a competent and committed group of professionals with sound knowledge

base and proficiency in project management, execution, procurement, inspection and site

co-ordination,

particularly expert in the management of international projects.

Our engineering work takes benefit from the wide know-how accumulated along 60 years of activity

with

more than 600 heaters and reformers supplied worldwide. Process design, base and detailed

engineering are

executed by our team of experienced engineers, which take advantage from the use of the most

advanced

calculations and design software, which makes our company a recognized leader in providing the most

sophisticated solutions to the Clients.

If required, the equipment is engineered in accordance to the basic design of International

Licensors like

UOP, Axens, Chevron, Haldor Topsøe, Davy Process Technology, KBR, Exxon, Stone&Webster, who selected

our Company as approved constructor.

Since its beginning the Company earned a solid reputation of competence and reliability and year

after year

gained the loyalty of the main international EPC Contractors and of the main Oil&Gas and

Petrochemical

Companies worldwide.

Equipment can be supplied worldwide either on FOB basis or on turn-key basis according to Customer

requirements.

Milestones Technical Evolution Kirchner Italia

Our Policy

QUALITY

Kirchner Italia works under:

- Quality Management System officially approved by Lloyd’s Register according to EN ISO 9001:2015.

- Policy for Enviromental Management according to EN ISO 14001:2015.

- Occupational Health and Safety Management according to EN ISO 45001:2018.

Company policy focus on the quality of the services and products in order to maintain the

satisfaction of the Clients in compliance with the above mentioned ISO Certifications.

The activities carried out on each job such as project management, design, engineering, procurement,

inspection and testing, construction supervision are all executed by Our experienced internal staff.

in this way we can assure an effective control of each engineering step and of the entire execution

of the project.

FLEXIBILITY

Kirchner Italia organization and flexibility allow to execute projects of any size and complexity.

It can execute short-term projects, adopting extraordinary procedures to accelerate the engineering

and procurement activities.

We can find the shop where to fabricate our furnaces all around the world, close to the site of

destination. Over the decades, Kirchner Italia have successfully implemented projects in full

compliance with international standards and have earned recognition for its objectivity, expertise

and efficiency. In terms of size, resources and capability, Kirchner ranks among the foremost

organizations of its kind.

CREATIVITY

Schedule constrains and/or high degree of prefabrication (modularization up to 100%) challenge our

Company to provide the most innovative and effective solutions.

Code of Ethics

More and more businesses today are called to take on a wider responsibility that does not end with

the economic effects of their activity, but that covers a variety of interests relevant to the

conservation of the natural environment, of health, work, and future well-being of the entire

community and the integrity of the system of social relations.

Along and parallel to the company’s range of interests, there has also been an increase in the

number of stakeholders with which the company must relate.

All internal and external parties that interface with the Company in the conduct of its business

should, therefore, be recognized as partners - or stakeholders - both because they contribute, in

various and specific ways, to the achievement of company goals, and because such activities affect

them positively or negatively.

These people are clients, shareholders, suppliers and employees, but also the entire

community.

Kirchner Italia S.p.A. has therefore decided to adopt a Code of Ethics with the intent to formalize

and crystallize the values in which it believes and which directs its activities.

Whistleblowing

Kirchner Italia S.p.A., in compliance with the current regulatory framework, has established an

internal system aimed at allowing so-called Whistleblowing Reports by internal/external parties in

relation to acts or facts that may constitute a violation of national and/or European regulations

applicable to the Company's activities. The system guarantees the confidentiality of the data and

personal information of the reporter, the alleged perpetrator of the violation, and others involved,

while ensuring the protection of the reporter from possible retaliatory and/or discriminatory

conduct.

Reports must be made:

- in good faith

- including precise details of the temporal and spatial circumstances under which the reported event

occurred

- by providing a clear description of the facts, including general information or other elements

that enable the person involved in the report to be identified

- it is also useful to attach documents that may provide evidence of the facts being reported, as

well as an indication of individuals who can help substantiate what was reported.

The Company makes it clear that reports based on mere suspicion or rumor or containing information

that the reporter knows to be false are not worthy of protection.

Specifically, behaviors consisting of:

1) Administrative, accounting, civil or criminal offenses;

2) illegal conduct relevant under Legislative Decree 231/2001 or violations of the Modelli di

Organizzazione, Gestione e Controllo della Società;

3) offenses within the scope of European Union or national acts with respect to public procurement;

financial services, products and markets and prevention of money laundering and terrorist financing;

product safety and compliance; transportation safety; environmental protection; radiation protection

and nuclear safety; food and feed safety and animal health and welfare; public health; consumer

protection; privacy and personal data protection; and network and information system security;

4) acts or omissions affecting the financial interests of the Union referred to in Article 325 of

the Treaty on the Functioning of the European Union specified in the relevant secondary legislation

of the European Union;

5) acts or omissions concerning the internal market, as referred to in Article 26(2) of the Treaty

on the Functioning of the European Union, including violations of the competition and state aid

rules of the European Union, as well as violations concerning the internal market related to acts

that violate the corporate tax rules or mechanisms whose purpose is to obtain a tax advantage that

frustrates the object or purpose of the applicable corporate tax law;

6) acts or conduct that frustrate the object or purpose of the provisions set forth in Union Acts in

the areas indicated in (3), (4) and (5);

7) all communications concerning reasonable and legitimate suspicion or awareness of potential or

actual violations of the regulations applicable to the Company or of facts and circumstances that

may cause damage to it or to third parties.

Submit a report through internal channels

It is possible to send a report to the Whistleblowing Manager, identified in the Organismo di

Vigilanza, and more precisely in the person of Mr. Oscar Marenzi, or to the Residual Channel

Referent, identified in the person of the Chairman of the Board of Statutory Auditors, Mr. Galeazzo

Montella:

- written and/or oral by logging on to the Kirchner Italy website www.kirchner.it

Whistleblowing Section: https://whistleblowersoftware.com/secure/9ad8f696-c1e9-4405-98c4-47a204d5a33d

- by requesting an in-person meeting by logging on to the Kirchner Italy website www.kirchner.it

Whistleblowing Section : https://whistleblowersoftware.com/secure/9ad8f696-c1e9-4405-98c4-47a204d5a33d

or by sending an email to:

o Whistleblowing Manager: drmarenzi@studioongaro-bg.191.it;

o Residual channel contact person: galeazzo.montella@avvocatimontella.it

For more information on the Portal and reporting channels, please see the related Whistleblowing

Procedure.

Response time

The Whistleblowing Officer will issue and send to the whistleblower:

- specific acknowledgement of receipt within 7 days with a concomitant summons if an in-person

meeting has been requested;

- feedback on the whistleblowing process - within 3 months from the date of acknowledgement of

receipt or, in the absence of such a notice, within 3 months from the expiration of the 7-day

deadline from the submission of the report - regarding, for example, dismissal of the report,

initiation of an internal investigation and, if applicable, its findings, steps taken to address

the issue raised, referral to a competent authority for further investigation.

Also, when:

- there is no mandatory activation of the internal reporting channel within its work context, or

this channel, even if mandatory, is not active or, even if activated, does not comply with the

provisions of the law;

- the reporting person has already made an internal report under Article 4 of Legislative Decree

No. 24/2023 and the report has not been followed up;

- the reporting person has reasonable grounds to believe that, if he or she made an internal

report, the report would not be effectively followed up or that the report itself might result

in the risk of retaliation;

- the reporting person has reasonable grounds to believe that the violation may pose an imminent

or obvious danger to the public interest

the report can be sent to the National Anticorruption Authority (ANAC) according to the specific

procedures published on the website.